Product Description

Cold/Warm forging realizes higher precision, greater strength, and improved wear resistance. Cold/Warm forging makes for a high production rate through material savings and requiring very little or no finishing work, and results in a significant reduction in cost. In the cold forging process, the workpiece is compressed in a mold at room temperature. In the case of warm forging, the workpiece is compressed in a mold below the recrystallization temperature, and has the advantage of forming a more complicated shape than in the cold forging process. We have achieved greater precision in the mass production of auto parts such as CV joints (produced by enclosed die forging), as well as products having a longitudinal bore spline configuration, gears for hydraulic machinery, and various industrial instruments.

Auto Parts by forging/Alloy Steel Forging products

We can offer you investment casting parts, railway casting parts, railway parts, excavator machinery parts, mining machinery parts, engineering machinery, agricultural machinery parts, sand casting, bucket tooth, auto parts, stamping & forging, and valve parts. We are capability in manufacture non-standard metal machining.

1. Investment casting sand casting/ lost wax casting/precision casting/gravity casting/stainless steel casting/carbon steel casting/ die casting/cookware handle casting/pan handle casting/home hardware casting;

2. Materials: Carbon steel, stainless steel, alloy steel and duplex steel, wcc, wcb, lcc, color metal etc;

3. Surface treatment: Heat treatment, machining, polishing, anodizing, hard anodizing, galvanized, enp, chrome plating, powder coating and painting;

4. Software for specification drawings: Pdf, auto CAD, solid work, proe;

5. Main production equipments: Wax injection, CNC-machine, heat treatment furnace;

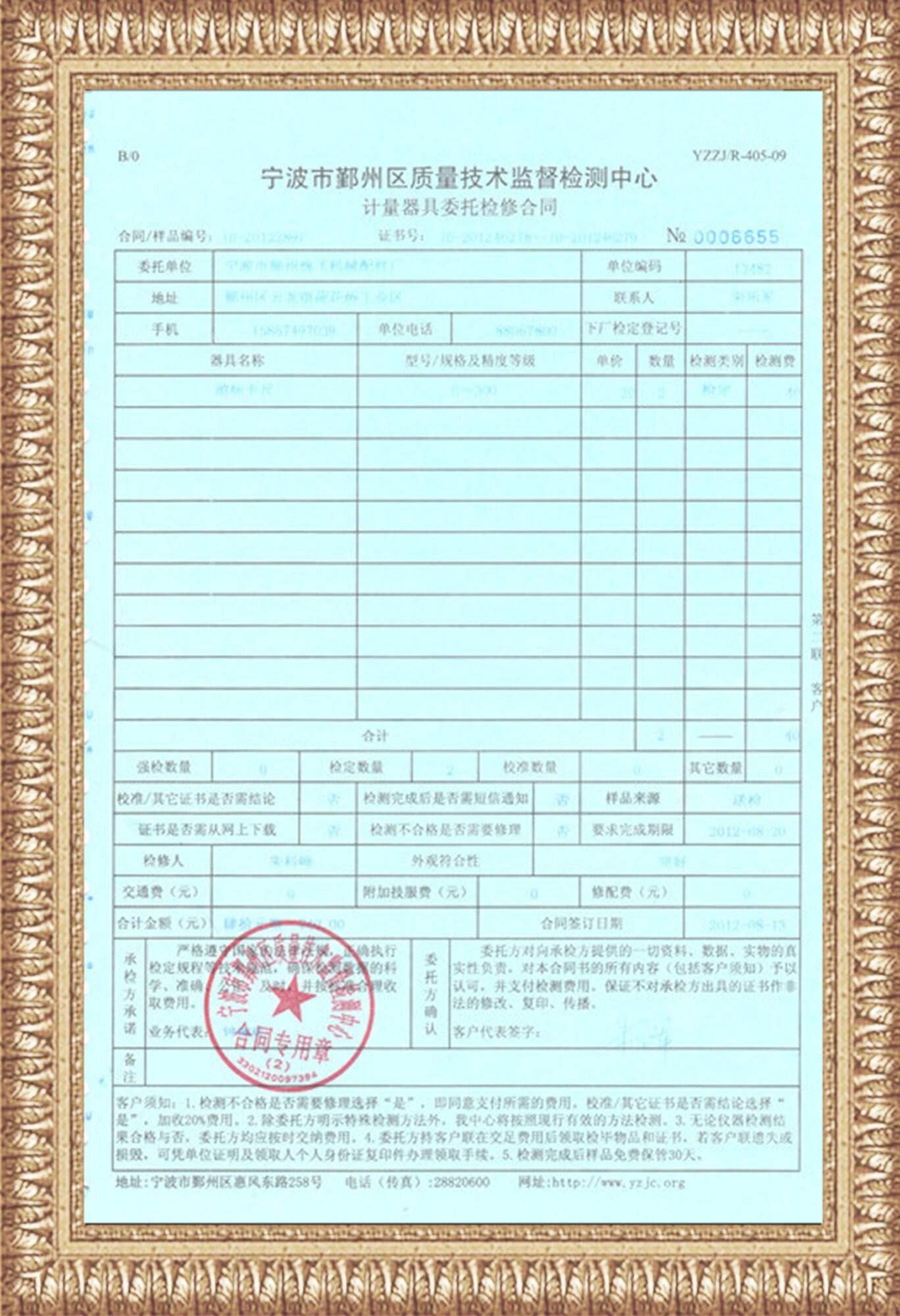

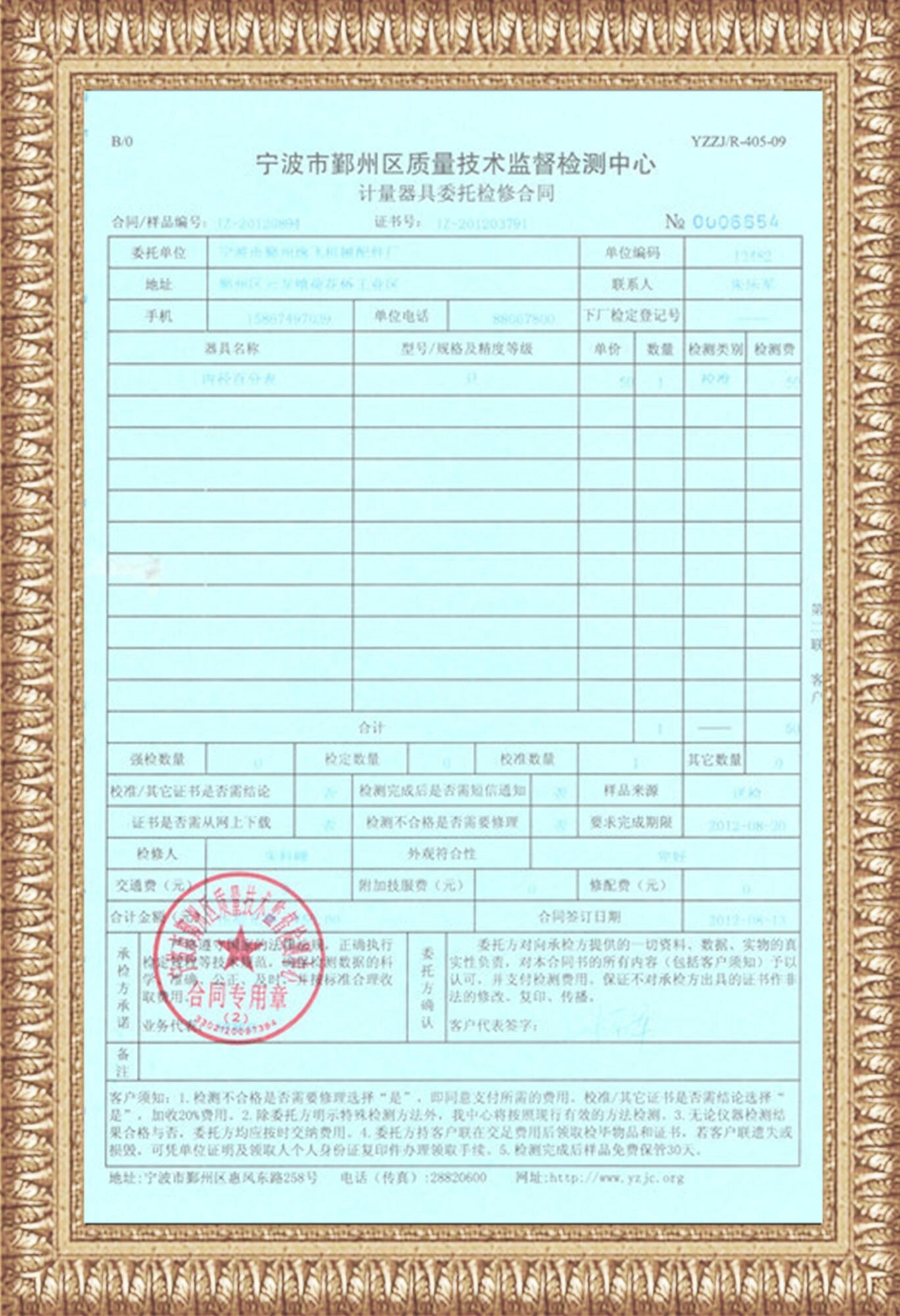

6. Quality assurance in accordance with ISO9001: 2008, strict material inspection and exact dimension control, 100% quality control.

7. OEM order is welcome;

8. The parts can be made completely based on your specifications such as drawing, design, sample etc.

English

English Deutsch

Deutsch 简体中文

简体中文