Product Description

The casting process may vary based on production volume and casting tolerance capability of the process. Hansheng helps their customers "engineer savings" by providing cost effective valve body castings design solutions, sourcing and warehousing.

Benefits of Valve Body Castings

-

The valve body castings shapes that can be produced are almost limitless.

-

With the correct valve body castings design and process many parts can be combined into a single part &emdash; helping reduce costs by reducing or eliminating machining, by providing assembly, as well as by reducing the number of components in inventory and other associated costs.

-

Design flexibility. Castings allow you to choose from many alloys as well as have flexibility for internal and external configurations to suit your particular needs. Net shape production is sometimes achievable so that the parts are usable as cast. However, to achieve many close tolerances, threads, or surface finishes machining is required. Hansheng can help minimize the need for expensive secondary operations by choosing an optimal casting process.

-

Elimination of material waste. valve body castings are cast to size.

-

The valve body castings is usually the most cost-effective method to produce complex or large parts for prototype quantities to medium and high-volume quantities.

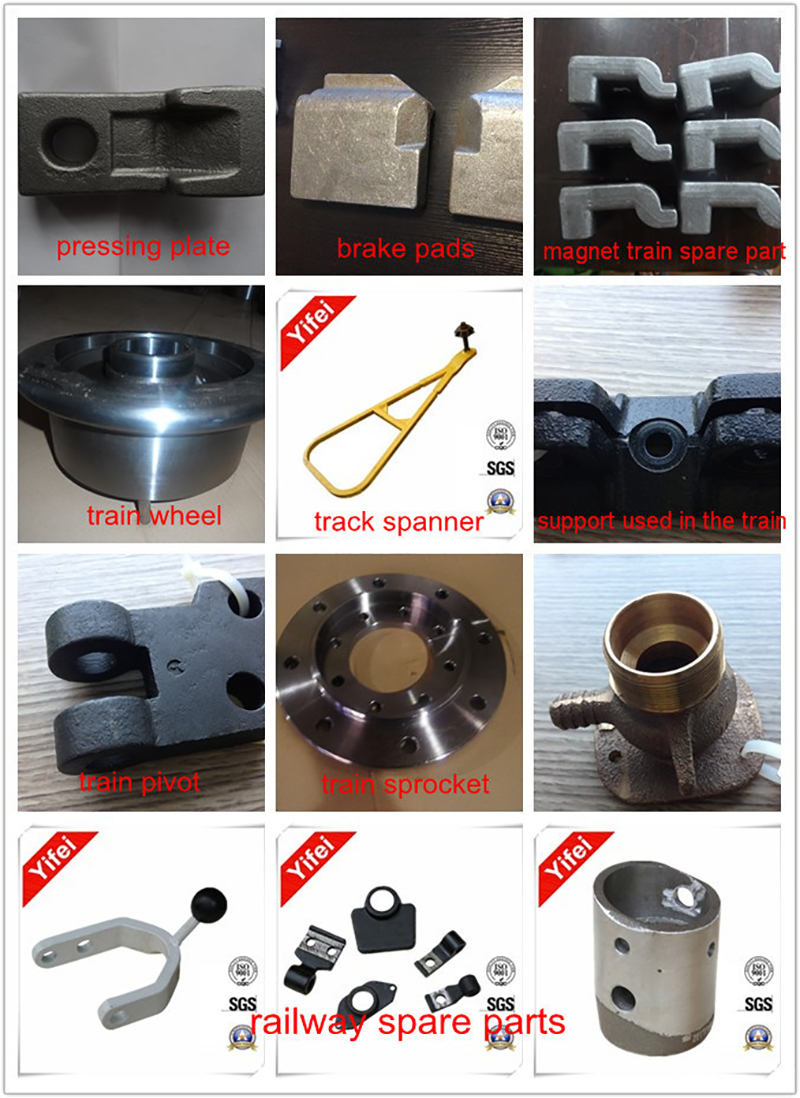

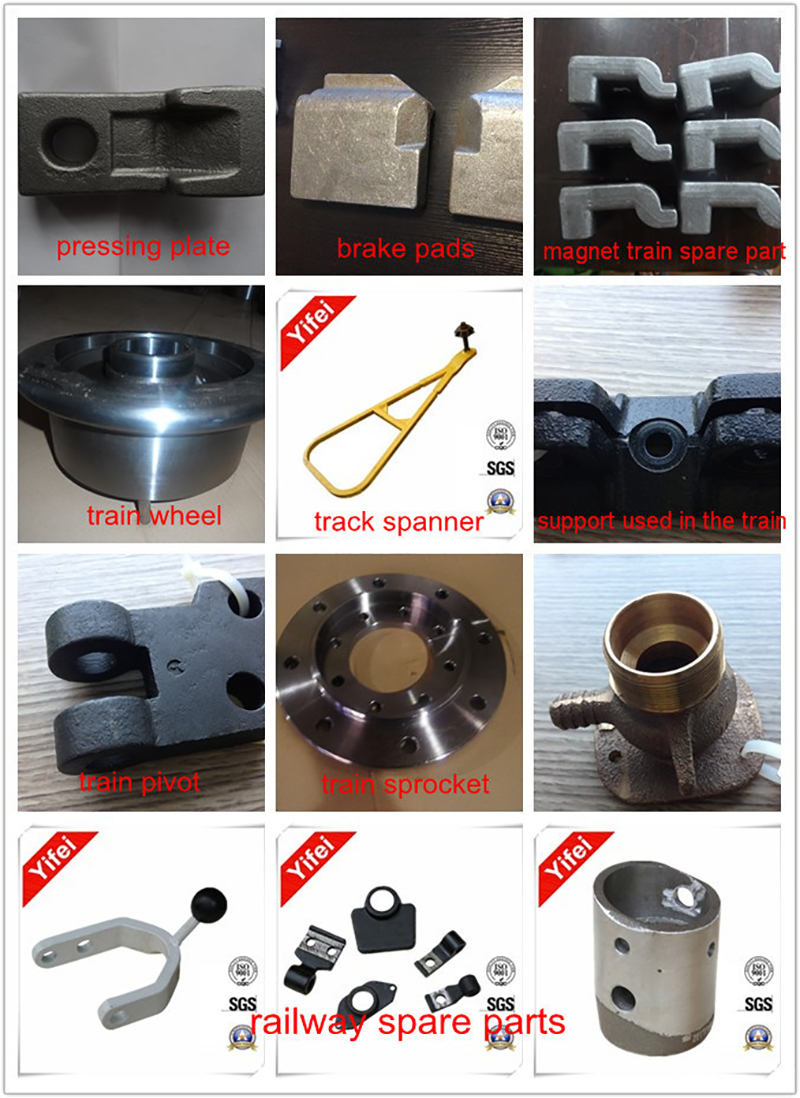

We can offer you investment casting parts, railway casting parts, railway parts, excavator machinery parts, mining machinery parts, engineering machinery, agricultural machinery parts, sand casting, bucket tooth, auto parts, stamping & forging, and valve parts. We are capability in manufacture non-standard metal machining.

1. Investment Casting Sand Casting/ Lost Wax Casting/Precision Casting/Gravity Casting/Stainless Steel Casting/Carbon Steel Casting/ Die Casting/Cookware Handle Casting/Pan Handle Casting/Home Hardware Casting;

2. Materials: Carbon Steel, Stainless Steel, Alloy Steel And Duplex Steel, Wcc, Wcb, Lcc, Color Metal etc;

3. Surface treatment: Heat treatment, machining, polishing, anodizing, hard anodizing, galvanized, enp, chrome plating, powder coating and painting;

4. Software for specification drawings: Pdf, auto CAD, solid work, proe;

5. Main production equipments: Wax injection, CNC-machine, heat treatment furnace;

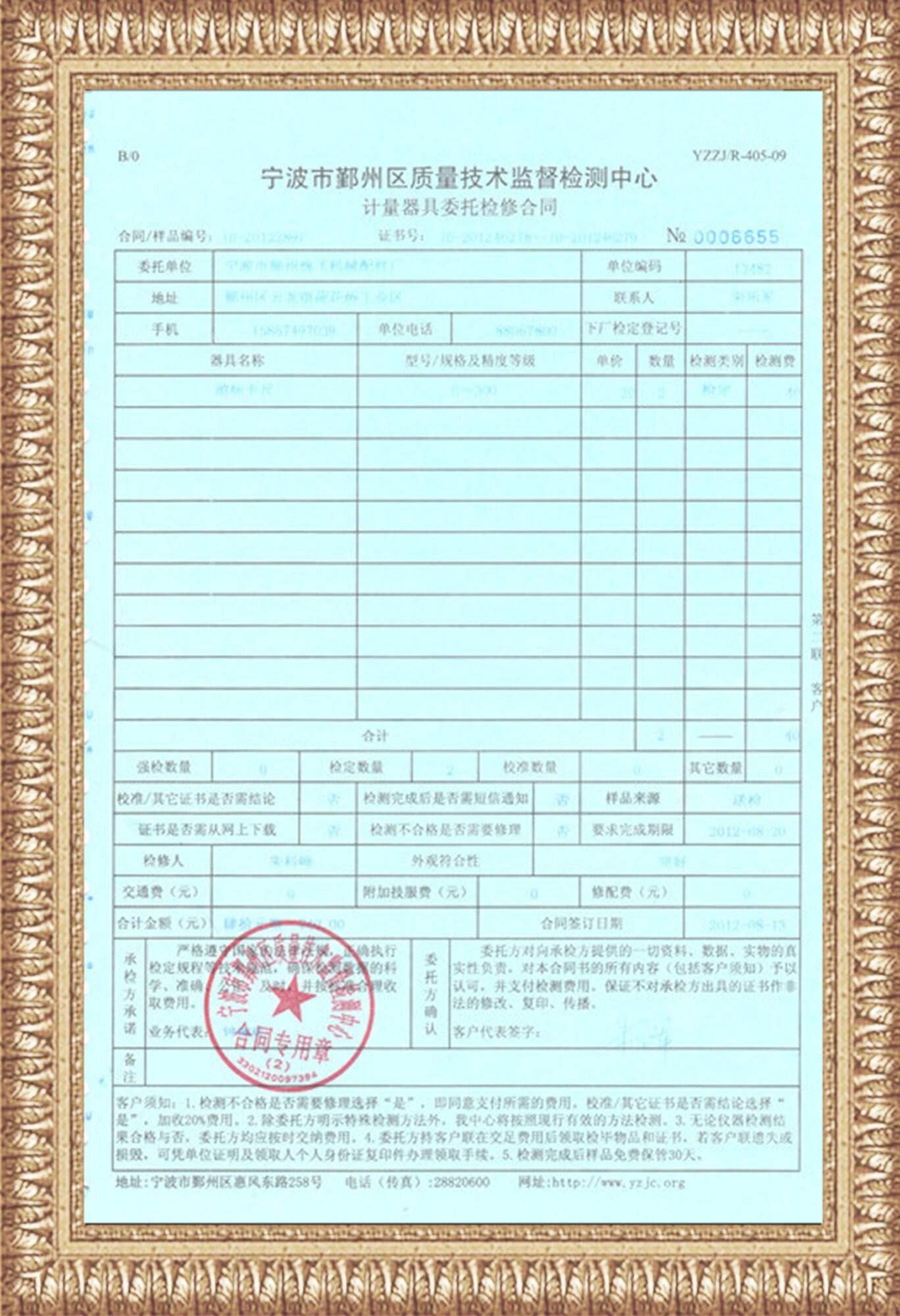

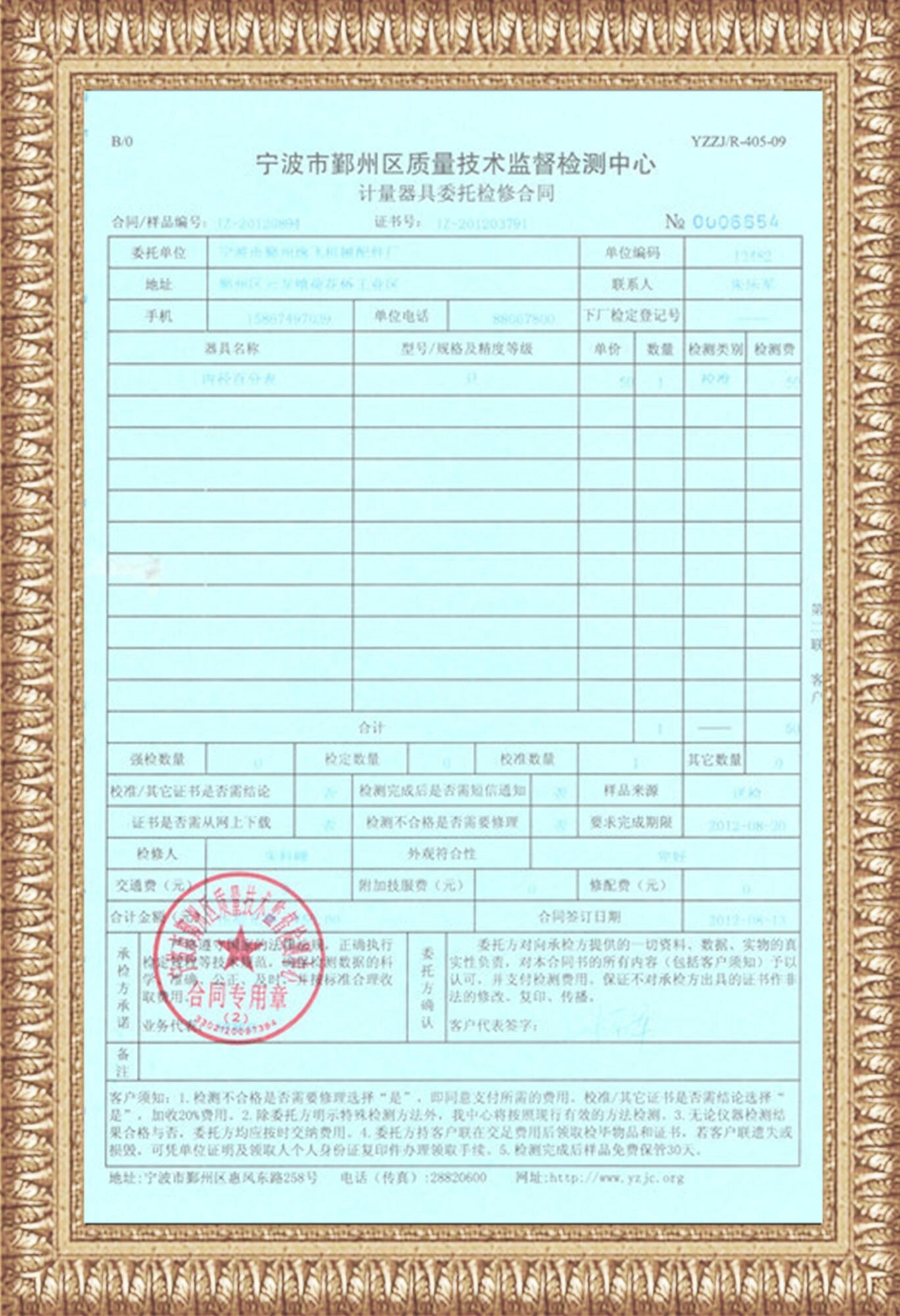

6. Quality assurance in accordance with ISO9001: 2008, strict material inspection and exact dimension control, 100% quality control.

7. OEM order is welcome;

8. The parts can be made completely based on your specifications such as drawing, design, sample etc.

English

English Deutsch

Deutsch 简体中文

简体中文